Advantages of Gravity Granular Multi Media Filters in SWRO Pre-treatment

The advantages of gravity granular multi media filters as a pre-treatment in SWRO plants is simply for better removal of algal material from the Seawater. Seawater always contains a measurable amount of algae, which concentration usually increases several times during the summer period and may increase up to 10 times during periods of algal blooms (which may or may not exhibit themselves as red tides).

There is a large variety of algal species in the seawater. Some algal species that occur during red tide events have cells that are relatively easy to break under pressure as low as 0.3 to 0.6 bars. When the algal cells break, they release cytoplasm in the seawater that has a very high content of easily biodegradable polysaccharides. When the amount of polysaccharides released by the broken algal cells exceeds certain level in the filtered seawater, they would typically trigger accelerated biofouling on the seawater reverse osmosis membranes.

Two practical approaches to address this type of problems are: (1) use of dissolved air flotation facility ahead of the pretreatment filters to gently remove algal cells and prevent their breakage (which is preferable); (2) installation of granular activated carbon media layer (cap) on the surface of the filters to remove some of the polysaccharides and other organics in the seawater. Pressure filters usually operate at several times higher pressure than gravity filters. Because the operating pressure of these filters is often higher than the algal cell break pressure threshold, pressure filters would have the disadvantage to cause an accelerated biofouling when filtering seawater of very high algal content. This effect is likely to manifest itself mainly in the summer and during algal blooms when the level of TOC in the source water

exceeds 2 mg/L. Pressure filters are frequently used in Spain and Australia. However, in most successful applications the source water quality is very good (TOC < 1 mg/L, SDI < 4 and turbidity < 4 NTU). Most of the Spanish desalination plant intakes are relatively deep and the algal content in the source water is fairly low. At depth of 10 to 20 m, the concentration of algae is significantly lower than that at the ocean surface – and therefore, as long as desalination plant intake is fairly deep, biofouling caused by breakage and decay of algal biomass may not be as significant problem as it would be for shallow intakes or intakes located at the ocean surface (i.e., near-shore open intakes).

Longer Useful Live of the Filter Structure

Typically, gravity filters are concrete structures that have useful life of 50 to 100 years. Pressure filters are steel structures with a lifespan of 25 years or less. The internal surface of the pressure filters used for seawater desalination is typically lined up with rubber coating that needs to be replaced every 5 to 10 years and inspected occasionally.

Lower Power Use

Because pressure filters typically operate at several times higher feed pressures than gravity filters, the energy use for pressure filtration is proportionally higher.

Higher Solids Retaining Capacity and Better Handling of Turbidity Spikes.

Gravity media filters have approximately two to three times larger volume of filtration media and retention time than pressure filters for the same water production capacity. Therefore, this type of filters can retain proportionally more solids and as a result, pretreatment filter performance is less sensitive to occasional spikes in turbidity of the source seawater. Pressure filters usually do not handle solids and turbidity spikes as well because of their smaller solids retention capacity (i.e., smaller volume of media pores that can store solids before the filter needs to be backwashed). If the source seawater is likely to experience occasional spikes of high turbidity (20 NTU or higher) due to rain events, algal tides, naval traffic, ocean bottom dredging operations in the vicinity of the intake, seasonal change in underwater current direction, or spring upwelling of water from the bottom to the surface, than pressure filters will produce effluent with inferior effluent quality (SDI and turbidity) during such events and therefore, their use would likely result in a more frequent RO cleaning.

Easier to Identify and Fix Filter Operational Problems

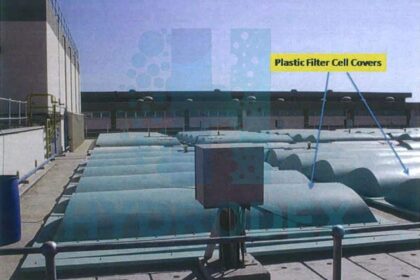

Gravity filters are typically covered with light plastic covers that protect the filter cells from direct sunlight.

Multi media filter in SWRO covered with a plastic filter cell cover

These covers however, can be easily removed and the filter cells can be inspected visually for irregularities – malfunctioning filter backwash nozzles, weir corrosion, poorly backwashed areas of filter media, formation of “mudballs “, etc. Pressure filters are completely enclosed and very difficult to inspect for the same problems. As a result, these filters have to be designed with higher contingency factor (reserve capacity). A 15 to 20 % reserve capacity is recommended if pressure filters are used to accommodate for potential flow distribution problems and uneven backwash air and water

distribution.

Easier to Accommodate Membrane Pretreatment in the Future

Currently, the existing commercial membrane MF/UF systems have not reached level of development that optimizes their application for seawater pretreatment of difficult to treat source seawater (i.e., seawater exposed to frequent algal blooms). However, in a not so distant future UF and MF membrane technology is expected to evolve into products specifically designed for pretreatment of seawater of high algal content. When this level of maturity of membrane pretreatment technology is reached, it likely would be very advantageous to modify the exiting conventional granular media filters into submersible membrane pretreatment filters. Although currently the market offers both pressure and vacuum-driven pretreatment systems, it is very likely that membrane pretreatment using vacuum-driven membranes would gain wider use, especially for applications where algal blooms in the seawater intake area are frequent events and pressure systems may be less advantageous. As long as gravity filter cells are designed with adequate depth and configuration to accommodate submersible UF/MF membranes, the transition to the new membrane pretreatment technology in the future would require limited additional costs. If pressure pretreatment filters are used, these filters cannot be easily modified into membrane pretreatment systems in the future.