Advantages of Gravity Granular Multi Media Filters in SWRO Pre-treatment

The advantages of gravity granular multi media filters as a pre-treatment in SWRO plants is simply for better removal of algal material from the Seawater. Seawater always contains a measurable amount of algae, which concentration usually increases several times during the summer period and may increase up to 10 times during periods of algal blooms (which may or may not exhibit themselves as red tides).

There is a large variety of algal species in the seawater. Some algal species that occur during red tide events have cells that are relatively easy to break under pressure as low as 0.3 to 0.6 bars. When the algal cells break, they release cytoplasm in the seawater that has a very high content of easily biodegradable polysaccharides. When the amount of polysaccharides released by the broken algal cells exceeds certain level in the filtered seawater, they would typically trigger accelerated biofouling on the seawater reverse osmosis membranes.

Two practical approaches to address this type of problems are: (1) use of dissolved air flotation facility ahead of the pretreatment filters to gently remove algal cells and prevent their breakage (which is preferable); (2) installation of granular activated carbon media layer (cap) on the surface of the filters to remove some of the polysaccharides and other organics in the seawater. Pressure filters usually operate at several times higher pressure than gravity filters. Because the operating pressure of these filters is often higher than the algal cell break pressure threshold, pressure filters would have the disadvantage to cause an accelerated biofouling when filtering seawater of very high algal content. This effect is likely to manifest itself mainly in the summer and during algal blooms when the level of TOC in the source water

exceeds 2 mg/L. Pressure filters are frequently used in Spain and Australia. However, in most successful applications the source water quality is very good (TOC < 1 mg/L, SDI < 4 and turbidity < 4 NTU). Most of the Spanish desalination plant intakes are relatively deep and the algal content in the source water is fairly low. At depth of 10 to 20 m, the concentration of algae is significantly lower than that at the ocean surface – and therefore, as long as desalination plant intake is fairly deep, biofouling caused by breakage and decay of algal biomass may not be as significant problem as it would be for shallow intakes or intakes located at the ocean surface (i.e., near-shore open intakes).

Longer Useful Live of the Filter Structure

Typically, gravity filters are concrete structures that have useful life of 50 to 100 years. Pressure filters are steel structures with a lifespan of 25 years or less. The internal surface of the pressure filters used for seawater desalination is typically lined up with rubber coating that needs to be replaced every 5 to 10 years and inspected occasionally.

Lower Power Use

Because pressure filters typically operate at several times higher feed pressures than gravity filters, the energy use for pressure filtration is proportionally higher.

Higher Solids Retaining Capacity and Better Handling of Turbidity Spikes.

Gravity media filters have approximately two to three times larger volume of filtration media and retention time than pressure filters for the same water production capacity. Therefore, this type of filters can retain proportionally more solids and as a result, pretreatment filter performance is less sensitive to occasional spikes in turbidity of the source seawater. Pressure filters usually do not handle solids and turbidity spikes as well because of their smaller solids retention capacity (i.e., smaller volume of media pores that can store solids before the filter needs to be backwashed). If the source seawater is likely to experience occasional spikes of high turbidity (20 NTU or higher) due to rain events, algal tides, naval traffic, ocean bottom dredging operations in the vicinity of the intake, seasonal change in underwater current direction, or spring upwelling of water from the bottom to the surface, than pressure filters will produce effluent with inferior effluent quality (SDI and turbidity) during such events and therefore, their use would likely result in a more frequent RO cleaning.

Easier to Identify and Fix Filter Operational Problems

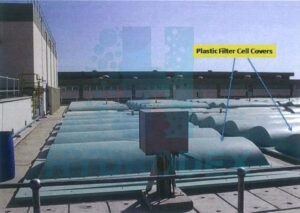

Gravity filters are typically covered with light plastic covers that protect the filter cells from direct sunlight.

Multi media filter in SWRO covered with a plastic filter cell cover

These covers however, can be easily removed and the filter cells can be inspected visually for irregularities – malfunctioning filter backwash nozzles, weir corrosion, poorly backwashed areas of filter media, formation of “mudballs “, etc. Pressure filters are completely enclosed and very difficult to inspect for the same problems. As a result, these filters have to be designed with higher contingency factor (reserve capacity). A 15 to 20 % reserve capacity is recommended if pressure filters are used to accommodate for potential flow distribution problems and uneven backwash air and water

distribution.

Easier to Accommodate Membrane Pretreatment in the Future

Currently, the existing commercial membrane MF/UF systems have not reached level of development that optimizes their application for seawater pretreatment of difficult to treat source seawater (i.e., seawater exposed to frequent algal blooms). However, in a not so distant future UF and MF membrane technology is expected to evolve into products specifically designed for pretreatment of seawater of high algal content. When this level of maturity of membrane pretreatment technology is reached, it likely would be very advantageous to modify the exiting conventional granular media filters into submersible membrane pretreatment filters. Although currently the market offers both pressure and vacuum-driven pretreatment systems, it is very likely that membrane pretreatment using vacuum-driven membranes would gain wider use, especially for applications where algal blooms in the seawater intake area are frequent events and pressure systems may be less advantageous. As long as gravity filter cells are designed with adequate depth and configuration to accommodate submersible UF/MF membranes, the transition to the new membrane pretreatment technology in the future would require limited additional costs. If pressure pretreatment filters are used, these filters cannot be easily modified into membrane pretreatment systems in the future.

Pressure Granular Media Filters

Pressure filters have filter bed configuration similar to that of gravity filers, except that the filter media is contained in steel pressure vessel. They have found application mainly for small and medium size seawater desalination plants – usually with production capacity of less than 20,000 m3/day. An exception is Spain, where practically all of the pretreatment filters at seawater desalination plants are pressure filters. In most cases for good source seawater quality (SDI < 5 and turbidity less than 5 NTU) the pressure filters are designed as single stage, dual media (anthracite and sand) units. Some plants with relatively poor water quality use two-stage pressure filtration systems. Pressure filters are available in two vessel configurations – vertical and horizontal. Vertical pressure filters (see Figure 15) are customarily used in smaller plants and individual vessels have maximum diameter of 3 m. Horizontal pressure filters (Figure 16) are used more frequently in desalination plants and are more popular for medium and large-size facilities. The largest desalination plant using horizontal pressure granular media filters for seawater pretreatment is the 160,000 m3/day Kwinana SWRO facility in Perth, Australia (see Figure 17). Horizontal filters allow larger filtration area per filter vessel as compared to vertical units. However, usually vertical vessels can de designed with deeper filter media, if deep filters are needed to handle spikes of source seawater turbidity.

Pressure Single-Stage Dual-Media Filters-Key Design Criteria

Compared to gravity media filters, which operate under a maximum water level over the filter bed of up to 2.5 meters, pressure filters typically run at feed pressure equivalent to 15 to 30 meters of water column. The magnitude of the feed pressure is often driven by the suction pressure requirements of the high pressure feed pumps of the downstream SWRO system. One key advantage of the pressure filters is that they could allow avoiding intermittent pumping of the pretreated seawater. A typical SWRO

system with gravity pretreatment filters requires installation of filter effluent transfer pumps to convey the filtrate from the filter effluent well to the high pressure SWRO feed pumps. Use of pressure filters could eliminate the need for such interim filter effluent transfer pumps because the filtrate is already pressure-driven by the intake pumps and the pretreatment filters do not break the hydraulic grade line.

Key design criteria for single-stage dual media pressure filters in small and medium size desalination plants are very similar to these of gravity filters. Design criteria by which pressure filers differ for gravity filters are presented below:

| Number of Filter Vessels | 6 to 20 |

| Filter Vessel Diameter | 1.2 to 6m (typically 3m) |

| Filter Vessel Length 2.5 to 15 m (typically 6 m) | Filter Vessel Length 2.5 to 15 m (typically 6 m) |

| Depth of Filter Bed | 0.6 to 0.9m |

| Filtration Rate (at Desalination Plant Intake Design Flow) | |

| With All Filters in Service | With All Filters in Service |

| Head loss Across the Filter Vessel | |

| Total Headless Across the Filter | 15 to 30m (20m average) |

| Net Headless Available for Filtration | 7.5 to 15m |

Horizontal Single Stage Granular Media Filter Pressure Vessel Made of Steel in Kwinana SWRO, Australia

Horizontal Granular Media Filter Pressure Vessel Made of Steel

Vertical Granular Media Filter Pressure Vessel Made of Steel

The design criteria presented above are guidelines – media size, depth and configuration, especially for medium and large desalination plants, are recommended to be selected based on pilot testing for the site specific conditions and water quality associated with the project.

Gravity Granular Media Pretreatment Filters Design Calculations

Gravity granular media filters are typically reinforced concrete structures that operate at water pressure drop through the media of between 1.8 m and 2.4 m. Single-stage dual media downflow gravity filters are predominant type of filtration pretreatment technology used in desalination plants of capacity higher than 40,000 m3/day. Downflow filters are preferred because they allow to retain algal biomass contained in the source seawater at the upper layer of the filter media and to minimize algal cell breakage which could cause release of soluble biodegradable organics in the filtered seawater.

Gravity Single Stage Dual Media Filters – Key Design Criteria and Considerations

Key design criteria for single-stage dual media gravity filters for medium and large size desalination plants are presented below:

| Filter type | Dual media, downflow, air-water backwash |

| Average Filter Cell Run Length | 24 h (between two filter cell backwashes) |

| Flow Distribution to individual cells | Pipe (if concrete channel used, channel depth should be tapered to keep velocity in the distribution channel above 2 m/sec at all times). |

| Number of Filter Cells | 8 to 16 (typically 12) |

| Filter Cell Width | 3 to 6 m |

| Filter Cell Depth | 4.5 to 7.5 m (typically 5 m) |

| Filter Cell Length-to-width ratio | 2:1 to 4:1 (typically 3:1) |

| Individual Filter Cell Area | 25 to 100 m2 |

| Maximum Water Depth Above Filter Bed | 2.5 m (should be equal or slightly higher than filter bed head loss which usually is 1.8 to 2.4m), |

| Filtration Rate (at Desalination Plant Intake Design Flow) | |

| With All Filters in Service | 8 to 10 m3/m2/h |

| With Two Filters Out of Service | 15 m3/m2/h |

| Filter Media | |

| Top Layer | Anthracite |

| Anthracite Layer – Depth | 1.5 m – 1.8 m (Deep Bed Filters – Recommended) |

| Anthracite Layer – Depth | 0.4 m – 0.8 m (Shallow Bed Filters – Used for Seawater of Low Turbidity (< 5 NTU) and Low Organics (TOC < 2 mg/l) |

| Anthracite – Effective Size | 0.8 to 2 (typical 1.5 mm) |

| Anthracite – Uniformity Coefficient | 1 .3 to 1. 7 (preferable < 1.4) |

| Anthracite – Specific Gravity | 1.5 to 1.6 tons/m3 |

| Anthracite – Bulk Density | 0.8 to 0.85 tons/m3 |

| Bottom Layer | Sand |

| Sand Layer – Depth | 1.0 to 2.0 m (Deep Bed Filters – Recommended) |

| Sand Layer – Depth | 0.4 to 0.6 m (Shallow Bed Filters). |

| Sand – Effective Size | 0.5mm |

| Sand – Uniformity coefficient | < 1.4 |

| Sand – Specific Gravity | 2.65 tons/m3 |

| Sand – Bulk Density | 1.5 to 1.9 tons/m3 |

| Filter Backwash System | Air – Water |

| Maximum Backwash Rate | 55 m3/m2/h |

| Average Backwash Rate | 40 – 45 m3/m2/h |

| Duration (Air + Water) | 40 – 60 min (includes filter cell draining & fill up). |

The design criteria presented above are guidelines only – media size, depth and configuration, especially for medium and large desalination plants, are recommended to be selected based on pilot testing for the site specific conditions and water quality associated with the project for a period that encompasses worst-case scenario water quality (i. e., significant rain events (rains of intensity higher than 15 mm), dredging near the intake area, red tide events, etc.). Table 3 provides examples of key design criteria for

desalination plants of various size and water quality.

| Desalination Plant Location and Capacity | Pretreatment System Configuration | Average and Maximum Filter Loading Rate | Notes |

| Glen Rocky SWRO Plant, Gibraltar – 1,400 m3/day | 4 single-stage media vertical pressure filters 90cm sand 30cm anthracite | 11 m3/m2/h (avg.) 16 m3/m2/h (max) |

Intake type – 2/3 of volume from wells and 1/3 from open intake |

| Ashkelon SWRO Plant, Israel – 325,000 m3/day | 40 single-stage dual

media gravity filters. |

8 m3/m2/h (avg.) 12 m3/m2/h (max) |

Offshore Submersed Open intake – 1000 m from shore. |

| Tuas Desalination Plant – 136,000 m3/day | Combined DAF and sand media filtration 110 cm-sand. | 10 m3/m2/h (avg.) 14 m3/m2/h (max\ |

Near Shore Open Intake in Singapore Industrial Port. |

| El Coloso SWRO Plant, Chile – 45,400 m3/day | DAF followed by Two stage Dual Media Horizontal Pressure Filters | DAF Surface Loading Rate – 22 to 33m3/m2/ h. Filtration Rate – 25 m3/m2/h (avg.) | Open Intake In Industrial Port Frequently Plagued by Red Tide Events. |

| Fujairah SWRO Plant, UAE – 1 70,500 m3/day | 14 Single-stage Dual Media Gravity Filters | Filtration Rate 8.5 m3/m2/h (avg.) 9.5 m3/m2/h (max) |

Open Intake – High Hydrocarbon Content of Seawater |

| Kwinana SWRO Plant, Perth, Australia – 160,000 m3/day | 24 single-stage dual media pressure filters | 14.0 m3/m’/h (avg.) 18.0 m3/m2/h (max) |

Offshore Submersed Open Intake |

| Carboneras SWRO Plant, Spain – 120,000 m3/day | 40 single-stage dual media pressure filters | 12.0 m3/m’/h (avg.) 14.0 m3/m2/h (max) |

Offshore Submersed Open Intake |

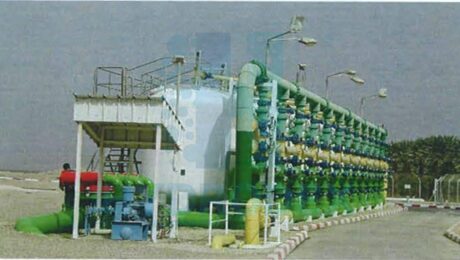

Some of the largest SWRO desalination plants in the world in operation today such as the 325,000 m3/day Ashkelon plant in Israel (Figure 1) are equipped with dual-media single-stage gravity filters.

Figure 1 – Ashkelon Seawater Desalination Plant Showing Pretreatment Filters

Back to Homepage

What is the Difference Between Pleated, String Wound and Melt Blown Filter Cartridges?

Each type of filter cartridges is acceptable for pretreatment to RO membranes. Pleated filter cartridge is typically used in higher purity applications such as pharmaceuticals and microelectronics. String wound filter cartridge is just as they sound; material such as polypropylene in string form which is wound around a central core. The disadvantage of these filter cartridges is that they suffer form particle unloading at higher pressure drops and require a slower velocity through them than other types of filter cartridges. Typically 2-3 gpm per 10 inch equivalent rather than 5 gpm per 10 inch equivalent for pleated and melt blown filter cartridges. The melt blown variety is thermally bonded polypropylene microfibers and is typically denser near the core than at the outside.

Read more about Hydrodex different types of filter cartridge.