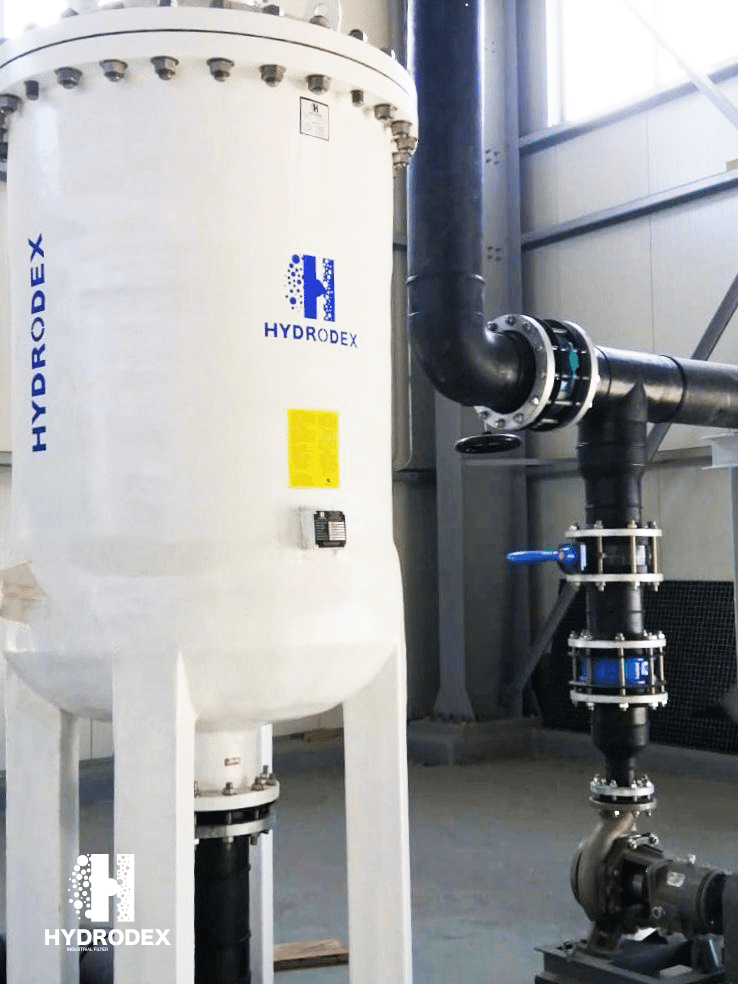

GRP Filter: A Key Technology for Water and Wastewater Treatment

In the field of water treatment, the (Glass Reinforced Plastic) GRP filter has become a prominent choice due to its durability, corrosion resistance, and efficiency. These filters are used in a wide variety of applications, from municipal water treatment to industrial wastewater management. But what exactly is a GRP filter, and how does it work? Let’s dive deeper into this innovative filtration technology and explore its benefits.

What Is a GRP Filter?

GRP filter is a type of filtration system made from glass-reinforced plastic, a composite material that combines fiberglass with resin. This material is lightweight, yet exceptionally strong and resistant to corrosion, making it ideal for applications that involve exposure to harsh chemicals, extreme weather conditions, or high pressures. The unique properties of GRP make these filters a preferred option in water treatment systems where longevity and resistance to chemical damage are essential.

How Does a GRP Filter Works?

GRP filter functions similarly to other types of filters, using physical mechanisms like mechanical filtration and adsorption to remove impurities from water or wastewater. Water is passed through a bed of filter media, such as sand, gravel, or activated carbon, which traps particles and contaminants.

GRP filter often comes in two configurations:

- Pressure Filters: GRP Cartridge Filter: These are pressurized systems, where water flows through the filter under pressure, forcing it through the cartridge filter element i.e: String Wound, Melt-Blown or Pleated Filter Cartridge.

- Gravity Filters: These rely on the natural force of gravity to pull water through the filter media – particularly: sand, gravel and anthracite and in smaller systems GAC (Granular Activated Carbon, GreenSand and Ion Exchange Resins) – making them suitable for removing particles of a certain micron size (up to 50 microns) and also Chlorine, Hardness (Ca + Mg) and Iron.

The filtration process can remove a wide range of contaminants, including:

- Suspended solids (e.g., dirt, sand, and silt)

- Organic matter (e.g., algae or bacteria)

- Chemicals and heavy metals (e.g., iron, chlorine, and fluoride)

Key Benefits of GRP Filters

-

Corrosion Resistance: One of the primary advantages of GRP filters is their resistance to corrosion. Unlike metal filters that can degrade over time when exposed to water and chemicals, GRP filters remain unaffected by rust, making them ideal for use in coastal or chemical-intensive environments.

-

Lightweight and Easy to Install: GRP filters are significantly lighter than metal or concrete alternatives, which makes them easier and more cost-effective to transport and install. This feature is particularly valuable in areas where infrastructure costs need to be minimized.

-

Durability: The glass-reinforced plastic construction offers exceptional strength, allowing GRP filters to withstand high pressures and temperatures. This durability translates into a long lifespan, reducing the need for frequent replacements and maintenance.

-

Cost-Effective: Although a GRP filter may have a higher upfront cost compared to some other materials, its long-term performance, low maintenance needs, and resistance to wear and tear makes it a cost-effective option in the long run.

-

Customizable: A GRP filter can be manufactured in a range of sizes and configurations, making it suitable for small-scale residential applications as well as large industrial and municipal systems.

Applications of a GRP Filter

GRP filter is versatile and find application in numerous industries and systems. Some of the most common uses include:

-

Municipal Water Treatment: A GRP filter are widely used in municipal water treatment plants to purify drinking water. It is ideal for removing particulate matter, microorganisms, and other contaminants from water before it reaches consumers.

-

Industrial Wastewater Treatment: In industries such as food processing, pharmaceuticals, and textiles, a GRP filter helps treat wastewater by removing suspended solids and chemicals, ensuring that the water meets environmental discharge standards.

-

Aquaculture: GRP filter is used in fish farms and other aquaculture applications to ensure that the water quality remains high by removing debris and maintaining a clean environment for aquatic life.

-

Swimming Pools: GRP filters are often found in swimming pool filtration systems, where it helps to remove fine particles and bacteria, ensuring that pool water remains safe and clean.

Maintenance and Considerations

While a GRP filter is relatively low-maintenance, it requires periodic cleaning and monitoring to ensure optimal performance. The filter media or cartridge filter elements may need to be replaced over time, depending on the type of contaminants being filtered and the volume of water being treated. Regular inspections of the GRP filter housing and pressure gauges are essential to identify any potential issues.

Additionally, it’s important to consider the quality of the incoming water, as very high levels of certain contaminants (e.g., iron or manganese) may require additional treatment steps, such as pre-filtration or chemical dosing, to optimize the performance of the GRP filter.

Conclusion

GRP filter offers a reliable, efficient, and cost-effective solution for water and wastewater filtration. With its corrosion resistance, durability, and ease of installation, it is an excellent choice for a wide range of applications, from municipal water treatment to industrial wastewater management. As water quality continues to be a priority in both residential and commercial sectors, the use of GRP filters will likely increase, ensuring cleaner water for people, industries, and the environment.

Hydrodex GRP Filter Housing