What is the Difference Between Pleated, String Wound and Melt Blown Filter Cartridges?

Each type of filter cartridges is acceptable for pretreatment to RO membranes. Pleated filter cartridge is typically used in higher purity applications such as pharmaceuticals and microelectronics. String wound filter cartridge is just as they sound; material such as polypropylene in string form which is wound around a central core. The disadvantage of these filter cartridges is that they suffer form particle unloading at higher pressure drops and require a slower velocity through them than other types of filter cartridges. Typically 2-3 gpm per 10 inch equivalent rather than 5 gpm per 10 inch equivalent for pleated and melt blown filter cartridges. The melt blown variety is thermally bonded polypropylene microfibers and is typically denser near the core than at the outside.

Read more about Hydrodex different types of filter cartridge.

Pleated Filter Cartridge

- Exceptional performance

- Long service life

- Lower energy and maintenance costs

- Low initial pressure drop

- Deliver high efficiency and consistent filtration of fluids in a wide range of critical applications

Features

- Pleated Filter design for best possible filtration in nominal and absolute ratings.

- Premium media provides up to 40% more capacity and 3 to 5 times longer service life than some pleated cartridges and with twice the flow rate of string wound or spun PP cartridges.

- Compatible with a wide range of chemicals and can be used at high temperatures.

- Dimensionaly precise.

- Single and double open-end (222 & 226 end-caps) available.

- Full range of micron levels.

- FDA compliant materials.

Specifications

- Micron Ratings: Nominal – 1.0, 3.0, 5.0, 10, 20,

30 & 50, Absolute: 0.2 & 0.5 - Dimensions: 2 5/8” or 2 3/4” Outside Diameter

1” Inner Diameter - Length: 10, 20, 30, 40 & 50” – 2 5/8” OD and 2 3/4″

Construction

- Inner polypropylene matrix core for optimal flow and superior intrinsic strength.

- Polyester or Polypropylene premium filter media is devoid of “blooming” organics and poisonous binders that clog up filter applications and may contaminate down-stream flow.

- Molded low-durometer plastisol end caps provide positive sealing in all housing types that require a knife edge seal.

Service

- Leading industry knowledge.

- Quick order turn-around.

- Exceptional customer service.

- Bring us your application and we will help you find the cartridge you need.

- Quick order turn-around.

- Bring us your application and we will help you find the cartridge you need.

Applications

- Food and Beverage Processing

- High Purity Chemicals

- RO Pretreatment

- Cosmetics and Fragrances

- Chemical Mechanical Polishing

- Photographic Solutions

- Metal Finishing/Plating Solutions

- Solvent Filtration

- Paints and Coatings

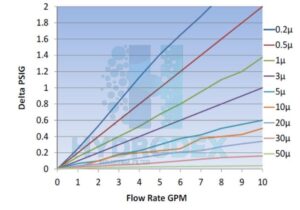

Liquid Flow Rate vs. Pressure

hydrodex pleated filter cartridge liquid flow rate vs pressure

Explore our other filters